-

Project Management Guide

- 1. Project Planning and Preparation 1. Project Planning and Preparation

- 2. Agile and Implementation 2. Agile and Implementation

- 3. Project Team 3. Project Team

- 4. Project Audit 4. Project Audit

- 5. Advice to Project Managers 5. Advice to Project Managers

- Project Survival, Support Services and SLA Project Survival, Support Services and SLA

-

Holistic Philosophy

- Philosophy of Workcube Philosophy of Workcube

- Workcube Manifesto Workcube Manifesto

-

Strategic Framework Guide

- 1. Strategic Framework Study 1. Strategic Framework Study

- 2. Competitive Analysis with the Diamond Model 2. Competitive Analysis with the Diamond Model

- 3. Value Proposition – Value Positioning 3. Value Proposition – Value Positioning

- 4. Digital Transformation Model 4. Digital Transformation Model

- 5. Business Model 5. Business Model

- 6. Organization Canvas 6. Organization Canvas

- 7. Basic Workflow 7. Basic Workflow

- 8. QPIC-RS Matrix 8. QPIC-RS Matrix

- 9. Time-Value Matrix 9. Time-Value Matrix

-

User Guide

- 1. General Usage and Basic Settings 1. General Usage and Basic Settings

- 1.1. Ecosystem and Users 1.1. Ecosystem and Users

- 1.2. Company Definition and Flow Parameters 1.2. Company Definition and Flow Parameters

- 1.3. Documentation and System Numbers 1.3. Documentation and System Numbers

- 1.4. Currency and Exchange Rates 1.4. Currency and Exchange Rates

- 1.5. Authority Groups 1.5. Authority Groups

- 1.5.1. Authorization Types 1.5.1. Authorization Types

- 1.5.1.1. GDPR Authorization 1.5.1.1. GDPR Authorization

- 1.5.2. Branch Office, Warehouse and Location Authorizations 1.5.2. Branch Office, Warehouse and Location Authorizations

- 1.6. Process Management and Workflows 1.6. Process Management and Workflows

- 1.6.1. QPIC - RS (Processes) 1.6.1. QPIC - RS (Processes)

- 1.6.2. Notifications and Approvals 1.6.2. Notifications and Approvals

- 1.6.3. Workflow Designer 1.6.3. Workflow Designer

- 1.7. Transaction Categories 1.7. Transaction Categories

- 1.9. Personalization and Personal Settings 1.9. Personalization and Personal Settings

- 1.10. WOC - Workcube Output Center 1.10. WOC - Workcube Output Center

- 1.10.1. Output Templates 1.10.1. Output Templates

- 1.11. Basket Settings and Usage 1.11. Basket Settings and Usage

- 1.11.1. Person-Account Selection Screens 1.11.1. Person-Account Selection Screens

- 1.12. Workcube Language Sets 1.12. Workcube Language Sets

- 1.13. Login and Active Directory 1.13. Login and Active Directory

- 1.14. Expense Receipts - Basket Columns 1.14. Expense Receipts - Basket Columns

- 1.15. Accounting Period 1.15. Accounting Period

- 1.16. Scheduled Tasks 1.16. Scheduled Tasks

- 1.17. Rounding Settings 1.17. Rounding Settings

- 1.18. System Mails 1.18. System Mails

- 1.19. How Does a Workcube Page Work? 1.19. How Does a Workcube Page Work?

- 1.21. Google Sheets - Workcube Integration 1.21. Google Sheets - Workcube Integration

- 2.1. ERP: Finance-Accounting-Budget 2.1. ERP: Finance-Accounting-Budget

- 2.1.1. Accounting Transactions 2.1.1. Accounting Transactions

- 2.1.1.1. Accounting Chart of Accounts 2.1.1.1. Accounting Chart of Accounts

- 2.1.1.1.1. Chart of Accounts Transfer 2.1.1.1.1. Chart of Accounts Transfer

- 2.1.1.1.2. Chart of Accounts at the Beginning of the Fiscal Year 2.1.1.1.2. Chart of Accounts at the Beginning of the Fiscal Year

- 2.1.1.1.3. Debt Inequality in Accounting Transactions 2.1.1.1.3. Debt Inequality in Accounting Transactions

- 2.1.1.1.4. Accounting Receipts 2.1.1.1.4. Accounting Receipts

- 2.1.1.2. Tax Definitions 2.1.1.2. Tax Definitions

- 2.1.1.4. Accounting Transaction Categories 2.1.1.4. Accounting Transaction Categories

- 2.1.1.5 5. Dimension Transaction 2.1.1.5 5. Dimension Transaction

- 2.1.2. Budget Planning and Control 2.1.2. Budget Planning and Control

- 2.1.2.1. Budget Categories and Budget Items 2.1.2.1. Budget Categories and Budget Items

- 2.1.2.3. Budget Dashboard 2.1.2.3. Budget Dashboard

- 2.1.2.4. Budget Transfer Request 2.1.2.4. Budget Transfer Request

- 2.1.3. Current Account and Transactions 2.1.3. Current Account and Transactions

- 2.1.3.1. Current Account Definitions 2.1.3.1. Current Account Definitions

- 2.1.3.2. Accounts and Contacts Accounting Definitions 2.1.3.2. Accounts and Contacts Accounting Definitions

- 2.1.3.3. Current Transactions 2.1.3.3. Current Transactions

- 2.1.3.4. Current Account Statement 2.1.3.4. Current Account Statement

- 2.1.3.5. Current Account Transfer 2.1.3.5. Current Account Transfer

- 2.1.4. Cash Account 2.1.4. Cash Account

- 2.1.4.1. Cash Account Management 2.1.4.1. Cash Account Management

- 2.1.4.2. Cash Payment 2.1.4.2. Cash Payment

- 2.1.4.3. Cash Flow 2.1.4.3. Cash Flow

- 2.1.4.4. Revenue and Expense Estimations 2.1.4.4. Revenue and Expense Estimations

- 2.1.4.5.1. Collection Forecast Analysis Report 2.1.4.5.1. Collection Forecast Analysis Report

- 2.1.4.7. Payment Receipt 2.1.4.7. Payment Receipt

- 2.1.5. Bank 2.1.5. Bank

- 2.1.5.1. Definition of Bank Transaction Categories 2.1.5.1. Definition of Bank Transaction Categories

- 2.1.5.4. Defining Bank Accounts 2.1.5.4. Defining Bank Accounts

- 2.1.5.5. Bank Account Openings 2.1.5.5. Bank Account Openings

- 2.1.5.8. What is Virtual Pos and How Does It Work? 2.1.5.8. What is Virtual Pos and How Does It Work?

- 2.1.5.8.1. Requirements for Virtual POS and Virtual POS Integration 2.1.5.8.1. Requirements for Virtual POS and Virtual POS Integration

- 2.1.5.9. Credit Cards 2.1.5.9. Credit Cards

- 2.1.5.10. Cash Deposit and Withdrawal 2.1.5.10. Cash Deposit and Withdrawal

- 2.1.5.11. Credit Card Payment/Collection Methods 2.1.5.11. Credit Card Payment/Collection Methods

- 2.1.5.12. Bank Instructions 2.1.5.12. Bank Instructions

- 2.1.5.16. Foreign Exchange Buy/Sale Transaction 2.1.5.16. Foreign Exchange Buy/Sale Transaction

- 2.1.6. Check - Note 2.1.6. Check - Note

- 2.1.6. Stamp Tax Declaration Preparation Report 2.1.6. Stamp Tax Declaration Preparation Report

- 2.1.6.1. Check Transactions 2.1.6.1. Check Transactions

- 2.1.6.1.1. Check Exit Registers 2.1.6.1.1. Check Exit Registers

- 2.1.6.1.2. Check/Note Transaction Categories 2.1.6.1.2. Check/Note Transaction Categories

- 2.1.6.2. Note Transactions 2.1.6.2. Note Transactions

- 2.1.6.2.1. Note Exit Registers 2.1.6.2.1. Note Exit Registers

- 2.1.7. Debt / Receivable Management 2.1.7. Debt / Receivable Management

- 2.1.7.1. Debt/Credit Breakdown 2.1.7.1. Debt/Credit Breakdown

- 2.1.7.2. Exchange Valuation Transactions 2.1.7.2. Exchange Valuation Transactions

- 2.1.7.3. Payment Performance 2.1.7.3. Payment Performance

- 2.1.7.4. Invoice Closing Transactions 2.1.7.4. Invoice Closing Transactions

- 2.1.7.5. Payment Requests 2.1.7.5. Payment Requests

- 2.1.8. Credit 2.1.8. Credit

- 2.1.8.1. Credit and Fund Management Transaction Categories 2.1.8.1. Credit and Fund Management Transaction Categories

- 2.1.8.9. Reconciliation 2.1.8.9. Reconciliation

- 2.1.8.9.10. RN-NS Notification 2.1.8.9.10. RN-NS Notification

- 2.1.9. Risk and Assurance 2.1.9. Risk and Assurance

- 2.1.9.1. Risk and Assurance Definitions 2.1.9.1. Risk and Assurance Definitions

- 2.1.9.4. Execution Proceedings 2.1.9.4. Execution Proceedings

- 2.1.9.6. Collaterals 2.1.9.6. Collaterals

- 2.1.10. Expense And Income Transactions 2.1.10. Expense And Income Transactions

- 2.1.10.1. Expense and Revenue Distribution Templates 2.1.10.1. Expense and Revenue Distribution Templates

- 2.1.10.2. Expense, Revenue and Maintenance Receipts XML Settings 2.1.10.2. Expense, Revenue and Maintenance Receipts XML Settings

- 2.1.11.4. Accounting Ledgers 2.1.11.4. Accounting Ledgers

- 2.1.11.6. Valuation and Rediscount Transaction Categories 2.1.11.6. Valuation and Rediscount Transaction Categories

- 2.1.11.7. Valuation and Rediscount 2.1.11.7. Valuation and Rediscount

- 2.1.11.8. Rediscount Transactions 2.1.11.8. Rediscount Transactions

- 2.1.12. Budget 2.1.12. Budget

- 2.1.12.1. Budget, Expense and Revenue Transaction Categories 2.1.12.1. Budget, Expense and Revenue Transaction Categories

- 2.1.12.2. Budget, Expense, and Revenue Process and Authorization 2.1.12.2. Budget, Expense, and Revenue Process and Authorization

- 2.1.12.3. Budget Planning Receipts 2.1.12.3. Budget Planning Receipts

- 2.1.13. Fixed Assets 2.1.13. Fixed Assets

- 2.1.13.1. Fixed Asset Transaction Categories 2.1.13.1. Fixed Asset Transaction Categories

- 2.1.13.8. Depreciation and Valuation 2.1.13.8. Depreciation and Valuation

- 2.1.14. Cost Accounting 2.1.14. Cost Accounting

- 2.1.15.1. End of Period and Fiscal Year Transition 2.1.15.1. End of Period and Fiscal Year Transition

- 2.1.17. Financial Statements 2.1.17. Financial Statements

- 2.1.17.1. Trial Balance 2.1.17.1. Trial Balance

- 2.1.17.3. Income Table 2.1.17.3. Income Table

- 2.1.18.1. What is Magic Accounter and How Can You Use It? 2.1.18.1. What is Magic Accounter and How Can You Use It?

- 2.1.18.2. What is Magic Auditor and How Can You Use It? 2.1.18.2. What is Magic Auditor and How Can You Use It?

- 2.1.18.3. What is Magic Budgeter? How to Use? 2.1.18.3. What is Magic Budgeter? How to Use?

- 2.1.19. Securities 2.1.19. Securities

- 2.1.20. e-Government 2.1.20. e-Government

- 2.1.20.1. e-Government Dashboard 2.1.20.1. e-Government Dashboard

- 2.1.20.2. What is e-Ledger? 2.1.20.2. What is e-Ledger?

- 2.1.20.3. What is e-Invoice? 2.1.20.3. What is e-Invoice?

- 2.1.20.3.1. E-Invoice Integration and Parametric Definitions 2.1.20.3.1. E-Invoice Integration and Parametric Definitions

- 2.1.20.3.2. Sending E-Invoice 2.1.20.3.2. Sending E-Invoice

- 2.1.20.3.3. Public e-Invoice 2.1.20.3.3. Public e-Invoice

- 2.1.20.3.4. Export e-Invoice 2.1.20.3.4. Export e-Invoice

- 2.1.20.4. What is e-Archive? 2.1.20.4. What is e-Archive?

- 2.1.20.4.1. E-Archive Integration and Parametric Definitions 2.1.20.4.1. E-Archive Integration and Parametric Definitions

- 2.1.20.4.2. E-Archive Submission 2.1.20.4.2. E-Archive Submission

- 2.1.20.5. What is e-Delivery Note? 2.1.20.5. What is e-Delivery Note?

- 2.1.21. Integration Between Accountant and Taxpayer 2.1.21. Integration Between Accountant and Taxpayer

- 2.2. Workcube SD / Sales Distribution 2.2. Workcube SD / Sales Distribution

- 2.2.1. Customer-Supplier Management 2.2.1. Customer-Supplier Management

- 2.2.1.1. Customer-Supplier Parametric Definitions 2.2.1.1. Customer-Supplier Parametric Definitions

- 2.2.1.2. Customer-Supplier Process Definitions and Transaction Categories 2.2.1.2. Customer-Supplier Process Definitions and Transaction Categories

- 2.2.1.3. Customers and Suppliers XML Settings 2.2.1.3. Customers and Suppliers XML Settings

- 2.2.1.4. Accounts 2.2.1.4. Accounts

- 2.2.1.4.1. Account Contacts 2.2.1.4.1. Account Contacts

- 2.2.1.4.2. Account Branch Offices 2.2.1.4.2. Account Branch Offices

- 2.2.1.5. Contacts 2.2.1.5. Contacts

- 2.2.1.6. Customer-Supplier Branch Office Relationship 2.2.1.6. Customer-Supplier Branch Office Relationship

- 2.2.1.7. BSC 2.2.1.7. BSC

- 2.2.1.8. Customer-Supplier Accounting Periods 2.2.1.8. Customer-Supplier Accounting Periods

- 2.2.1.9. Customer-Supplier Member Information 2.2.1.9. Customer-Supplier Member Information

- 2.2.2.1. Product Management 2.2.2.1. Product Management

- 2.2.2.1.1. Product Parametric Definitions 2.2.2.1.1. Product Parametric Definitions

- 2.2.2.1.2. Product Process Definitions 2.2.2.1.2. Product Process Definitions

- 2.2.2.1.3. Product XML Settings 2.2.2.1.3. Product XML Settings

- 2.2.2.1.4. Product Category Management 2.2.2.1.4. Product Category Management

- 2.2.2.1.5. Product Configurations 2.2.2.1.5. Product Configurations

- 2.2.2.1.6. Product Feature Definitions and Variation Management 2.2.2.1.6. Product Feature Definitions and Variation Management

- 2.2.2.1.6.1. Measurement and Allocation Table 2.2.2.1.6.1. Measurement and Allocation Table

- 2.2.2.1.7. Product Accounting Account Definitions 2.2.2.1.7. Product Accounting Account Definitions

- 2.2.2.1.9. Basic Product Definitions 2.2.2.1.9. Basic Product Definitions

- 2.2.2.1.10. Product Price Detail 2.2.2.1.10. Product Price Detail

- 2.2.2.1.11. Pricing the Product, Entering Conditions, Inventory Status 2.2.2.1.11. Pricing the Product, Entering Conditions, Inventory Status

- 2.2.2.1.12. Product Detail and Product General Parameters 2.2.2.1.12. Product Detail and Product General Parameters

- 2.2.2.1.13. Mixed Parcel 2.2.2.1.13. Mixed Parcel

- 2.2.2.1.14. Product-Inventory Selection Lists 2.2.2.1.14. Product-Inventory Selection Lists

- 2.2.2.1.15. Serial Number and Lot Tracking 2.2.2.1.15. Serial Number and Lot Tracking

- 2.2.2.1.16. Print Batch Barcode 2.2.2.1.16. Print Batch Barcode

- 2.2.2.1.17. Product Purchase-Sale Conditions 2.2.2.1.17. Product Purchase-Sale Conditions

- 2.2.2.1.18. Product Quality Control Definitions 2.2.2.1.18. Product Quality Control Definitions

- 2.2.2.1.19. Model Product 2.2.2.1.19. Model Product

- 2.2.2.1.19.1. Model-Product Cost and Supply Plan 2.2.2.1.19.1. Model-Product Cost and Supply Plan

- 2.2.2.1.20. Label 2.2.2.1.20. Label

- 2.2.2.2. Competition Management 2.2.2.2. Competition Management

- 2.2.2.3. Inventory Management 2.2.2.3. Inventory Management

- 2.2.2.3.1. Inventories XML Settings 2.2.2.3.1. Inventories XML Settings

- 2.2.2.3.2. Inventory Detail 2.2.2.3.2. Inventory Detail

- 2.2.2.3.3. Fundamentals of Inventory Management 2.2.2.3.3. Fundamentals of Inventory Management

- 2.2.2.3.4. Inventory Strategies 2.2.2.3.4. Inventory Strategies

- 2.2.2.3.5. Zero Inventory Working Principles 2.2.2.3.5. Zero Inventory Working Principles

- 2.2.2.3.6. Inventory-Spec Transactions 2.2.2.3.6. Inventory-Spec Transactions

- 2.2.2.6. e-Delivery Note 2.2.2.6. e-Delivery Note

- 2.2.3. Price Management 2.2.3. Price Management

- 2.2.3.1. Price Lists 2.2.3.1. Price Lists

- 2.2.3.2. Price Editing and Transfer 2.2.3.2. Price Editing and Transfer

- 2.2.3.3. Price Recommendations 2.2.3.3. Price Recommendations

- 2.2.3.4. Special Prices and Discounts 2.2.3.4. Special Prices and Discounts

- 2.2.4. Cost 2.2.4. Cost

- 2.2.4.1. Cost Parametric Definitions 2.2.4.1. Cost Parametric Definitions

- 2.2.4.2. Product Costs 2.2.4.2. Product Costs

- 2.2.4.2.1. Product Cost in Workcube 2.2.4.2.1. Product Cost in Workcube

- 2.2.4.3. Inventory Costs 2.2.4.3. Inventory Costs

- 2.2.4.4. Product Cost and Profit Margins 2.2.4.4. Product Cost and Profit Margins

- 2.2.4.5. Distribution of Consumables and Material Loss Receipts to Expense Centers 2.2.4.5. Distribution of Consumables and Material Loss Receipts to Expense Centers

- 2.2.4.6. Production Estimated Cost 2.2.4.6. Production Estimated Cost

- 2.2.4.7. Re-Cost 2.2.4.7. Re-Cost

- 2.2.5.1. Agreements 2.2.5.1. Agreements

- 2.2.5.3. Price Difference and Bonus Controls 2.2.5.3. Price Difference and Bonus Controls

- 2.2.6. Warehouse and Space Management 2.2.6. Warehouse and Space Management

- 2.2.7. Shipment - Logistics Management 2.2.7. Shipment - Logistics Management

- 2.2.7.1. Shipment - Logistics Parametric Definitions 2.2.7.1. Shipment - Logistics Parametric Definitions

- 2.2.7.2. Shipment-Logistics Processes and Transaction Categories 2.2.7.2. Shipment-Logistics Processes and Transaction Categories

- 2.2.7.3. Inventory Transactions 2.2.7.3. Inventory Transactions

- 2.2.7.4. Shipment-Logistics Orders 2.2.7.4. Shipment-Logistics Orders

- 2.2.7.5. Purchase Delivery Notes 2.2.7.5. Purchase Delivery Notes

- 2.2.7.6. Sales Delivery Notes 2.2.7.6. Sales Delivery Notes

- 2.2.7.7. Inter-Warehouse Transfer Delivery Note 2.2.7.7. Inter-Warehouse Transfer Delivery Note

- 2.2.7.8. Shipping Request 2.2.7.8. Shipping Request

- 2.2.7.9. Inventory Receipts 2.2.7.9. Inventory Receipts

- 2.2.7.10. Inventory Opening (Carryforward) Receipt 2.2.7.10. Inventory Opening (Carryforward) Receipt

- 2.2.7.11. Inventory Transfer 2.2.7.11. Inventory Transfer

- 2.2.7.12. Spec Transfer 2.2.7.12. Spec Transfer

- 2.2.7.13. Stock-taking Transactions 2.2.7.13. Stock-taking Transactions

- 2.2.7.14. In-Group Transactions 2.2.7.14. In-Group Transactions

- 2.2.7.16. Delivery Note - Order Relation and Shipment Methods of Orders 2.2.7.16. Delivery Note - Order Relation and Shipment Methods of Orders

- 2.2.7.17. Inventory Carryforward Slip and Inventory Age Calculation 2.2.7.17. Inventory Carryforward Slip and Inventory Age Calculation

- 2.2.7.18. Serial Number Warranty Tracking on Delivery Note 2.2.7.18. Serial Number Warranty Tracking on Delivery Note

- 2.2.7.19. Packaging and Shipments 2.2.7.19. Packaging and Shipments

- 2.2.7.19.1. Packages 2.2.7.19.1. Packages

- 2.2.7.20. Shipment - Logistics | Map 2.2.7.20. Shipment - Logistics | Map

- 2.2.7.21. Team Planning 2.2.7.21. Team Planning

- 2.2.7.22. Returns 2.2.7.22. Returns

- 2.2.7.23. Consignment Transactions 2.2.7.23. Consignment Transactions

- 2.2.7.24. Batch Shipment Planning 2.2.7.24. Batch Shipment Planning

- 2.2.8. Sales Management 2.2.8. Sales Management

- 2.2.8.1. Sales Management Parametric Definitions 2.2.8.1. Sales Management Parametric Definitions

- 2.2.8.2. Sales Management XML Settings 2.2.8.2. Sales Management XML Settings

- 2.2.8.3. Sales Management Process Definitions 2.2.8.3. Sales Management Process Definitions

- 2.2.8.4. Sales Proposals 2.2.8.4. Sales Proposals

- 2.2.8.5. Sales Orders 2.2.8.5. Sales Orders

- 2.2.8.6. Installments Sales 2.2.8.6. Installments Sales

- 2.2.8.7. Sales Map 2.2.8.7. Sales Map

- 2.2.9. Purchasing Management 2.2.9. Purchasing Management

- 2.2.9.1. Purchasing Parametric Definitions 2.2.9.1. Purchasing Parametric Definitions

- 2.2.9.2. Purchasing XML Settings 2.2.9.2. Purchasing XML Settings

- 2.2.9.3. Purchasing Processes and Transaction Categories 2.2.9.3. Purchasing Processes and Transaction Categories

- 2.2.9.4. Internal Requests 2.2.9.4. Internal Requests

- 2.2.9.5. Internal Request Listing 2.2.9.5. Internal Request Listing

- 2.2.9.6. Purchase Request 2.2.9.6. Purchase Request

- 2.2.9.7. Purchase Offers 2.2.9.7. Purchase Offers

- 2.2.9.7.1. Purchase Offer Evaluations and Received Offer Acceptance 2.2.9.7.1. Purchase Offer Evaluations and Received Offer Acceptance

- 2.2.9.8. Purchase Orders 2.2.9.8. Purchase Orders

- 2.2.9.9. Place Batch Order 2.2.9.9. Place Batch Order

- 2.2.11.1. Invoice Parametric Definitions 2.2.11.1. Invoice Parametric Definitions

- 2.2.11.2. Invoice Processes and Transaction Categories 2.2.11.2. Invoice Processes and Transaction Categories

- 2.2.11.3. Invoice Issue Orders 2.2.11.3. Invoice Issue Orders

- 2.2.11.4. Sales Invoice 2.2.11.4. Sales Invoice

- 2.2.11.4.1. Issued Service Invoice 2.2.11.4.1. Issued Service Invoice

- 2.2.11.4.2. Issued Proforma Invoice 2.2.11.4.2. Issued Proforma Invoice

- 2.2.11.4.3. Issued Progress Payment Invoice 2.2.11.4.3. Issued Progress Payment Invoice

- 2.2.11.4.5. Issued Exchange Rate Difference Invoice 2.2.11.4.5. Issued Exchange Rate Difference Invoice

- 2.2.11.4.6. VAT Exempt Sales Invoice 2.2.11.4.6. VAT Exempt Sales Invoice

- 2.2.11.4.7. Purchase Return Invoice 2.2.11.4.7. Purchase Return Invoice

- 2.2.11.4.8. Issued Delay Interest Invoice 2.2.11.4.8. Issued Delay Interest Invoice

- 2.2.11.4.9. Export Invoice 2.2.11.4.9. Export Invoice

- 2.2.11.4.10. Unpaid Non-Quota Export Invoice 2.2.11.4.10. Unpaid Non-Quota Export Invoice

- 2.2.11.4.12. Invoices Including Withholding 2.2.11.4.12. Invoices Including Withholding

- 2.2.11.5. Purchase Invoice 2.2.11.5. Purchase Invoice

- 2.2.11.5.1. Goods Purchase Invoice 2.2.11.5.1. Goods Purchase Invoice

- 2.2.11.5.3. Received Progress Payment Invoice 2.2.11.5.3. Received Progress Payment Invoice

- 2.2.11.5.4. Received Services Invoice 2.2.11.5.4. Received Services Invoice

- 2.2.11.5.5. Received Proforma Invoice 2.2.11.5.5. Received Proforma Invoice

- 2.2.11.5.6. Received Exchange Rate Difference Invoice 2.2.11.5.6. Received Exchange Rate Difference Invoice

- 2.2.11.5.7. Received Delay Interest Invoice 2.2.11.5.7. Received Delay Interest Invoice

- 2.2.11.5.8. Note of Expenses - Services 2.2.11.5.8. Note of Expenses - Services

- 2.2.11.5.9. Note of Expense - Goods 2.2.11.5.9. Note of Expense - Goods

- 2.2.11.5.11. Import Invoice 2.2.11.5.11. Import Invoice

- 2.2.11.5.12. Self-Employed Invoice 2.2.11.5.12. Self-Employed Invoice

- 2.2.11.5.13. Retail Sales Return Invoice 2.2.11.5.13. Retail Sales Return Invoice

- 2.2.11.5.14. Wholesale Return Invoice 2.2.11.5.14. Wholesale Return Invoice

- 2.2.11.5.15. Retail Sales Invoice 2.2.11.5.15. Retail Sales Invoice

- 2.2.11.6. Difference Invoice in Health Expenditures 2.2.11.6. Difference Invoice in Health Expenditures

- 2.2.12.4. Imported Goods Entry 2.2.12.4. Imported Goods Entry

- 2.2.12.5. Import Transactions 2.2.12.5. Import Transactions

- 2.2.14. Promotion Management 2.2.14. Promotion Management

- 2.2.14.1. Promotions 2.2.14.1. Promotions

- 2.2.14.3. TPD (Trade Promotions and Discounts) 2.2.14.3. TPD (Trade Promotions and Discounts)

- 2.2.14.4. Active Promotions 2.2.14.4. Active Promotions

- 2.2.14.5. Shopping Coupons 2.2.14.5. Shopping Coupons

- 2.3. MM - Production 2.3. MM - Production

- 2.3.1. Production Design 2.3.1. Production Design

- 2.3.1.1. Production Design Parametric Definitions 2.3.1.1. Production Design Parametric Definitions

- 2.3.1.2. Production Design Page Settings (XML) Settings 2.3.1.2. Production Design Page Settings (XML) Settings

- 2.3.1.3. Production Design Processes and Transaction Categories 2.3.1.3. Production Design Processes and Transaction Categories

- 2.3.1.4. BOM Design 2.3.1.4. BOM Design

- 2.3.1.4.2. CLO3D Workcube Integration 2.3.1.4.2. CLO3D Workcube Integration

- 2.3.1.5. Production Work Centers and Operations 2.3.1.5. Production Work Centers and Operations

- 2.3.1.6. BOMs Revision Management 2.3.1.6. BOMs Revision Management

- 2.3.1.7. Alternative Raw Material Management 2.3.1.7. Alternative Raw Material Management

- 2.3.1.8. Spec Management with Alternative Product Questions 2.3.1.8. Spec Management with Alternative Product Questions

- 2.3.1.8.1. Alternative Product Variation Product Structure (BOM) 2.3.1.8.1. Alternative Product Variation Product Structure (BOM)

- 2.3.2. Production Planning 2.3.2. Production Planning

- 2.3.2.1. Production Planning Page Settings (XML) Settings 2.3.2.1. Production Planning Page Settings (XML) Settings

- 2.3.2.2. Production Planning Processes and Transaction Categories 2.3.2.2. Production Planning Processes and Transaction Categories

- 2.3.2.3. Production Requests 2.3.2.3. Production Requests

- 2.3.2.4. Production - Orders 2.3.2.4. Production - Orders

- 2.3.2.5. Production Orders 2.3.2.5. Production Orders

- 2.3.2.5.1. Grouping Function 2.3.2.5.1. Grouping Function

- 2.3.2.7. Production Results 2.3.2.7. Production Results

- 2.3.2.8. In Production 2.3.2.8. In Production

- 2.3.2.9. Material Requirements 2.3.2.9. Material Requirements

- 2.3.2.10. Chart 2.3.2.10. Chart

- 2.3.2.11. Production Operations List 2.3.2.11. Production Operations List

- 2.3.3. Production 2.3.3. Production

- 2.3.3.1. Production Page Settings (XML) Settings 2.3.3.1. Production Page Settings (XML) Settings

- 2.3.3.2. Production Transactions 2.3.3.2. Production Transactions

- 2.3.3.2.1. Serial Number in Production Processes 2.3.3.2.1. Serial Number in Production Processes

- 2.4. Quality Control Processes 2.4. Quality Control Processes

- 2.4.1. Laboratory Operations 2.4.1. Laboratory Operations

- 2.4.2. Quality Control Grouping 2.4.2. Quality Control Grouping

- 3. Workcube HR / Human Resources 3. Workcube HR / Human Resources

- 3.1. Organization Planning 3.1. Organization Planning

- 3.1.3.1. Google Maps - Branch Offices 3.1.3.1. Google Maps - Branch Offices

- 3.1.7. Top Level Units 3.1.7. Top Level Units

- 3.1.8. Organizational Chart 3.1.8. Organizational Chart

- 3.1.9. Charts 3.1.9. Charts

- 3.3. Human Resources Operations 3.3. Human Resources Operations

- 3.3.1. Human Resources Recruitment and Selection 3.3.1. Human Resources Recruitment and Selection

- 3.3.1.9. Orientation Training 3.3.1.9. Orientation Training

- 3.3.2. Human Resources Employee Recruitment 3.3.2. Human Resources Employee Recruitment

- 3.3.2.1. Trial Process Forms 3.3.2.1. Trial Process Forms

- 3.3.2.2. Human Resources Officer Recruitment and Payroll 3.3.2.2. Human Resources Officer Recruitment and Payroll

- 3.3.2.3. Defining Human Resources Additional Allowance 3.3.2.3. Defining Human Resources Additional Allowance

- 3.3.3. Payroll Rules 3.3.3. Payroll Rules

- 3.3.3.3. Wage Rules 3.3.3.3. Wage Rules

- 3.3.5. Timekeeping Transactions 3.3.5. Timekeeping Transactions

- 3.3.5.1. Mail Sending in Timekeeping 3.3.5.1. Mail Sending in Timekeeping

- 3.3.5.3. Additional Allowance Definitions 3.3.5.3. Additional Allowance Definitions

- 3.3.5.4. Timekeeping Sequential Transactions 3.3.5.4. Timekeeping Sequential Transactions

- 3.3.5.5. Payrolling 3.3.5.5. Payrolling

- 3.3.5.6. Accounting and Budgeting of Timekeeping 3.3.5.6. Accounting and Budgeting of Timekeeping

- 3.3.5.7. Dynamic Payroll 3.3.5.7. Dynamic Payroll

- 3.3.5.8. Salary Payments 3.3.5.8. Salary Payments

- 3.3.5.9. Execution Applications 3.3.5.9. Execution Applications

- 3.3.5.9.1. Deduction Application from Fixed Amount in Execution 3.3.5.9.1. Deduction Application from Fixed Amount in Execution

- 3.3.5.10. Tax Statement/Declaration 3.3.5.10. Tax Statement/Declaration

- 3.3.5.11. Viewing Tax Statement/Declaration Files 3.3.5.11. Viewing Tax Statement/Declaration Files

- 3.3.5.12. Advance Request 3.3.5.12. Advance Request

- 3.3.5.15. Leaves and Seniority Information Transactions 3.3.5.15. Leaves and Seniority Information Transactions

- 3.3.6. Attendance and Control 3.3.6. Attendance and Control

- 3.3.6.1. List of EATS 3.3.6.1. List of EATS

- 3.3.6.2. Branch Office Based EATS 3.3.6.2. Branch Office Based EATS

- 3.3.6.3. Shifts 3.3.6.3. Shifts

- 3.3.6.4. EATS Status 3.3.6.4. EATS Status

- 3.3.6.5. Subcontractor EATS List 3.3.6.5. Subcontractor EATS List

- 3.3.6.6. Attendance and Control Definitions 3.3.6.6. Attendance and Control Definitions

- 3.3.6.7. Import EATS Transactions 3.3.6.7. Import EATS Transactions

- 3.3.7. Work Schedule and Shift Management 3.3.7. Work Schedule and Shift Management

- 3.3.8. Use of Leave or Free Time for Overtime 3.3.8. Use of Leave or Free Time for Overtime

- 3.3.9. Short Work Allowance 3.3.9. Short Work Allowance

- 3.3.10. Individual Pension System - Automation 3.3.10. Individual Pension System - Automation

- 3.3.10. Travel Allowance 3.3.10. Travel Allowance

- 3.3.11. Import EATS Rules 3.3.11. Import EATS Rules

- 3.3.12. Workcube Message Management System 3.3.12. Workcube Message Management System

- 3.4.1. Workplace Audit Procedures 3.4.1. Workplace Audit Procedures

- 3.4.1.2. Health Expenditure Receipts 3.4.1.2. Health Expenditure Receipts

- 3.5. Work Accidents 3.5. Work Accidents

- 3.6. Health Assurance System 3.6. Health Assurance System

- 3.6.1. Health Expenses, Payroll and Accounting 3.6.1. Health Expenses, Payroll and Accounting

- 3.7. Role Planning 3.7. Role Planning

- 3.7.1. Roles-Positions 3.7.1. Roles-Positions

- 3.7.1.1. Position Types and Definitions 3.7.1.1. Position Types and Definitions

- 3.7.1.2. How to Update Roles-Positions? 3.7.1.2. How to Update Roles-Positions?

- 3.7.1.3. How to List Roles-Positions? 3.7.1.3. How to List Roles-Positions?

- 3.7.2. Transferring Position Task 3.7.2. Transferring Position Task

- 3.7.3. Mass Position Change 3.7.3. Mass Position Change

- 3.7.4. Supervisors and Backups 3.7.4. Supervisors and Backups

- 3.7.5. Promotion and Rotation Requests 3.7.5. Promotion and Rotation Requests

- 3.7.6. Job Definitions 3.7.6. Job Definitions

- 3.7.7. Permanent Staff 3.7.7. Permanent Staff

- 3.7.8. Permanent Staff Vacancies/Excess 3.7.8. Permanent Staff Vacancies/Excess

- 3.7.8.1. Organization Simulator 3.7.8.1. Organization Simulator

- 3.7.9. Competency Definitions 3.7.9. Competency Definitions

- 3.7.10. Mandates 3.7.10. Mandates

- 3.7.11. Employees Eligible for Qualifications 3.7.11. Employees Eligible for Qualifications

- 3.7.12. Designation Promotional Forms 3.7.12. Designation Promotional Forms

- 3.8. Performance Management 3.8. Performance Management

- 3.8.1. Assessment and Evaluation Forms 3.8.1. Assessment and Evaluation Forms

- 3.8.2. Performance Management Parametric Definitions 3.8.2. Performance Management Parametric Definitions

- 3.9. Disciplinary and Other Actions 3.9. Disciplinary and Other Actions

- 3.9.1. Event Report 3.9.1. Event Report

- 4. CRM-Customer Relationship Management 4. CRM-Customer Relationship Management

- 4.1. Customer/Contact Management 4.1. Customer/Contact Management

- 4.2. Sales and Marketing 4.2. Sales and Marketing

- 4.2.1. Sales Force Management 4.2.1. Sales Force Management

- 4.2.1.1. Regional Planning and Sales Teams 4.2.1.1. Regional Planning and Sales Teams

- 4.2.1.2. Target and Quotas 4.2.1.2. Target and Quotas

- 4.2.2.1. Interactions 4.2.2.1. Interactions

- 4.2.2.2. Customer Visits and Meetings 4.2.2.2. Customer Visits and Meetings

- 4.2.2.3. Opportunities 4.2.2.3. Opportunities

- 4.2.2.3.1. Opportunity Management Parametric Definitions 4.2.2.3.1. Opportunity Management Parametric Definitions

- 4.2.3. Marketing 4.2.3. Marketing

- 4.2.3.1. Campaign Management 4.2.3.1. Campaign Management

- 4.2.3.2. Events 4.2.3.2. Events

- 4.2.3.3. Target Group 4.2.3.3. Target Group

- 4.2.3.4. Account Analysis Forms 4.2.3.4. Account Analysis Forms

- 4.2.3.5. Survey Management 4.2.3.5. Survey Management

- 4.2.3.6. Posts and Mailing Lists 4.2.3.6. Posts and Mailing Lists

- 4.2.3.7. SendGrid Mail Integration 4.2.3.7. SendGrid Mail Integration

- 4.3. Service-Warranty Management 4.3. Service-Warranty Management

- 4.3.1. Call Center 4.3.1. Call Center

- 4.3.1.1. Call Center Parametric Definitions 4.3.1.1. Call Center Parametric Definitions

- 4.3.1.2. Call Center Page Settings 4.3.1.2. Call Center Page Settings

- 4.3.1.3. Search Contact 4.3.1.3. Search Contact

- 4.3.1.4. Call Center Applications 4.3.1.4. Call Center Applications

- 4.3.1.6. Phone - Call Center 4.3.1.6. Phone - Call Center

- 4.3.2. Service Management 4.3.2. Service Management

- 4.3.2.1. Service-Warranty Parametric Definitions 4.3.2.1. Service-Warranty Parametric Definitions

- 4.3.2.1.1. Service Applications 4.3.2.1.1. Service Applications

- 4.3.2.1.2. Service Operations 4.3.2.1.2. Service Operations

- 4.3.2.1.3. Service Maintenance Results 4.3.2.1.3. Service Maintenance Results

- 4.3.2.1.4. Maintenance Plans 4.3.2.1.4. Maintenance Plans

- 4.3.2.1.5. Warranty and Product Tracking 4.3.2.1.5. Warranty and Product Tracking

- 4.3.2.1.6. Service Work Groups 4.3.2.1.6. Service Work Groups

- 4.3.2.2 Service Management XML Settings 4.3.2.2 Service Management XML Settings

- 5. Subscription Management 5. Subscription Management

- 5.1. Subscription Parametric Definitions 5.1. Subscription Parametric Definitions

- 5.2. Subscription Page Settings 5.2. Subscription Page Settings

- 5.3. Subscription Authorization and Processes 5.3. Subscription Authorization and Processes

- 5.4. Subscription Registration and Contract 5.4. Subscription Registration and Contract

- 5.5. Subscription Service and Pricing (Payment Plan) 5.5. Subscription Service and Pricing (Payment Plan)

- 5.5.1. Subscription Committed Campaign Management 5.5.1. Subscription Committed Campaign Management

- 5.6. Invoicing Transactions 5.6. Invoicing Transactions

- 5.7. Collection and Taking Automatic Payment 5.7. Collection and Taking Automatic Payment

- 5.8. Counter Transactions 5.8. Counter Transactions

- 5.9. Tariffs 5.9. Tariffs

- 6. PAM - Physical Asset Management 6. PAM - Physical Asset Management

- 6.1. Physical Assets 6.1. Physical Assets

- 6.1.1. Machinery-Equipments and Buildings 6.1.1. Machinery-Equipments and Buildings

- 6.1.2. IT Assets 6.1.2. IT Assets

- 6.1.3. Physical Asset Debit Processes 6.1.3. Physical Asset Debit Processes

- 6.1.4. Shared Use 6.1.4. Shared Use

- 6.1.5. Physical Assets Parametric Definitions 6.1.5. Physical Assets Parametric Definitions

- 6.2. Motor Vehicle Management 6.2. Motor Vehicle Management

- 6.2.1. Motor Vehicles 6.2.1. Motor Vehicles

- 6.2.1.1. Motor Vehicles Parametric Definitions 6.2.1.1. Motor Vehicles Parametric Definitions

- 6.2.1.2. Asset Demands 6.2.1.2. Asset Demands

- 6.2.2. Vehicle Purchase-Sales 6.2.2. Vehicle Purchase-Sales

- 6.2.3. KM Control Management 6.2.3. KM Control Management

- 6.2.4. Fuel Control Management 6.2.4. Fuel Control Management

- 6.2.5. Accident-Penalty Management 6.2.5. Accident-Penalty Management

- 6.3. Repair-Maintenance Management 6.3. Repair-Maintenance Management

- 6.3.1. Failure Notifications 6.3.1. Failure Notifications

- 6.3.2. Repair-Maintenance Plan and Results 6.3.2. Repair-Maintenance Plan and Results

- 6.3.3. Repair-Maintenance Schedule 6.3.3. Repair-Maintenance Schedule

- 6.3.4. Repair-Maintenance Receipts 6.3.4. Repair-Maintenance Receipts

- 7. PMS - Project Management 7. PMS - Project Management

- 7.1.1. Project Requirements and Material Plans 7.1.1. Project Requirements and Material Plans

- 7.1.2. Operations Under the Project 7.1.2. Operations Under the Project

- 7.1.3. Projects XML Settings 7.1.3. Projects XML Settings

- 7.1.4. Project Management Parametric Definitions 7.1.4. Project Management Parametric Definitions

- 7.1.5. Project Management Processes 7.1.5. Project Management Processes

- 7.2.1. Related Tasks 7.2.1. Related Tasks

- 7.3. Project Dashboard 7.3. Project Dashboard

- 7.4. Workboard 7.4. Workboard

- 7.5. Google Drive - Workcube Integration 7.5. Google Drive - Workcube Integration

- 7.6. Time Management 7.6. Time Management

- 9. LMS Training Management 9. LMS Training Management

- 9.1. Lesson 9.1. Lesson

- 9.2. Training Management Parametric Definitions 9.2. Training Management Parametric Definitions

- 10. Intranet 10. Intranet

- 10.1. Intranet Transactions 10.1. Intranet Transactions

- 10.2. Google Calendar - Workcube Integration 10.2. Google Calendar - Workcube Integration

- 10.4. Literature 10.4. Literature

- 10.5. Digital Archive 10.5. Digital Archive

- 10.6. Self-Service HR Transactions 10.6. Self-Service HR Transactions

- 10.7. Self Service Other Processes 10.7. Self Service Other Processes

- 10.8. Library 10.8. Library

- 10.9. Web Phone Usage 10.9. Web Phone Usage

- 10.10. ChatFlow 10.10. ChatFlow

- 10.11. Forum 10.11. Forum

- 10.12. Calendar 10.12. Calendar

- 11.3. Career Portal with Protein 11.3. Career Portal with Protein

- 11.4. Creating a Website with Protein 11.4. Creating a Website with Protein

- 11.5. Creating Pages for Protein Sites 11.5. Creating Pages for Protein Sites

- 11.6. The Concept and Use of Widget in Protein 11.6. The Concept and Use of Widget in Protein

- 11.7. Concept and Use of Design Block in Protein 11.7. Concept and Use of Design Block in Protein

- 12. Workcube Whops 12. Workcube Whops

- 12.1. WHOPS Dashboard 12.1. WHOPS Dashboard

- 13.1. Content Management 13.1. Content Management

- 13.1.1. Contents 13.1.1. Contents

- 13.1.2. Banner Management 13.1.2. Banner Management

- 13.2. Worktips 13.2. Worktips

- 14.1. Period Transactions 14.1. Period Transactions

- 14.2. General Settings 14.2. General Settings

- 14.3. Import 14.3. Import

- 14.4. Utility 14.4. Utility

- 14.5. Maintenance 14.5. Maintenance

- 14.5.4. Workcube Upgrade 14.5.4. Workcube Upgrade

-

Technical Documents

- Active Directory Usage Active Directory Usage

- Communication services and CF Web Socket Communication services and CF Web Socket

- Dev, QA, Release, Live - EN Dev, QA, Release, Live - EN

- Digital Archive File Upload Digital Archive File Upload

- How should you protect your system against increasing security risks? How should you protect your system against increasing security risks?

- How to configure Security Templates? How to configure Security Templates?

- How to Use Workcube - Google Integration? How to Use Workcube - Google Integration?

- Log4j Security Vulnerability Log4j Security Vulnerability

- Release Transition and Upgrade from Master Release Transition and Upgrade from Master

- VSCode Workcube Extension VSCode Workcube Extension

- W-Error Mechanism and Error Outputs W-Error Mechanism and Error Outputs

- Workcube and Authenticator Application Workcube and Authenticator Application

- Workcube Cargo Integrations Workcube Cargo Integrations

- Workcube DB Structures Workcube DB Structures

-

Development

- 1. Development Environment – Software Languages 1. Development Environment – Software Languages

- 1.1. Workcube Software Components 1.1. Workcube Software Components

- 1.1.1. What is WO - Workcube Objects? 1.1.1. What is WO - Workcube Objects?

- 1.1.2. WEX Components 1.1.2. WEX Components

- 1.2. Workcube and Git 1.2. Workcube and Git

- 1.3. The Power of JAVA - The Convenience of Coldfusion 1.3. The Power of JAVA - The Convenience of Coldfusion

- 1.4. Contemporary Code Development Techniques 1.4. Contemporary Code Development Techniques

- 1.5. Debug Reading and Interpretation 1.5. Debug Reading and Interpretation

- 1.6. SOLR and Content Management 1.6. SOLR and Content Management

- 1.7. Customization Options 1.7. Customization Options

- 1.8. Developing Google Forms Tool with App Script 1.8. Developing Google Forms Tool with App Script

- 1.9. Voice Search and Read Aloud 1.9. Voice Search and Read Aloud

- 2. W3 Code Library 2. W3 Code Library

- 2.1. AjaxFormSubmit ve AjaxPageLoad 2.1. AjaxFormSubmit ve AjaxPageLoad

- 2.2. AjaxLoader, AjaxControlPostData and AjaxControlGetData 2.2. AjaxLoader, AjaxControlPostData and AjaxControlGetData

- 2.3. QofQ - Query of Queries 2.3. QofQ - Query of Queries

- 2.4. Autocomplete and Ready-to-Use Workdata 2.4. Autocomplete and Ready-to-Use Workdata

- 2.5. Validation and Methods 2.5. Validation and Methods

- 2.8. Filter, Map and Reduce Operations 2.8. Filter, Map and Reduce Operations

- 2.9. What is WRO and How Is It Written? 2.9. What is WRO and How Is It Written?

- 2.10. Sales Order and Reserve Transactions 2.10. Sales Order and Reserve Transactions

- 2.11. What is the Nocode Model? 2.11. What is the Nocode Model?

- 2.11.1. Nocode Usage and Flow 2.11.1. Nocode Usage and Flow

- 3. Custom Tags 3. Custom Tags

- 3.1. cf_get_workcube_note 3.1. cf_get_workcube_note

- 3.2. cf_get_workcube_asset 3.2. cf_get_workcube_asset

- 3.3. cf_barcode / Custom Tag 3.3. cf_barcode / Custom Tag

- 3.4. cf_wrk_cash / Custom Tag 3.4. cf_wrk_cash / Custom Tag

- 3.5. cf_loader 3.5. cf_loader

- 3.6. cf_box 3.6. cf_box

- 3.7. cf_workcube_websocket 3.7. cf_workcube_websocket

- 3.8. cf_box_search 3.8. cf_box_search

- 3.9. cf_workcube_process 3.9. cf_workcube_process

- 3.10. cf_workcube_general_process 3.10. cf_workcube_general_process

- 3.10. Language Customtags and Usage 3.10. Language Customtags and Usage

- 3.11. cf_duxi 3.11. cf_duxi

- 3.12. wrkIbanCode 3.12. wrkIbanCode

- 3.13. cf_language_info / Custom Tag 3.13. cf_language_info / Custom Tag

- 3.14. cf_publishing_settings 3.14. cf_publishing_settings

- 3.16. cf_puxild 3.16. cf_puxild

- 3.17. cf_send_woc 3.17. cf_send_woc

- 3.15 cf_wrkdepartmentlocation 3.15 cf_wrkdepartmentlocation

- 4. NoCode FrameWork 4. NoCode FrameWork

- 4.1. Remote Development with VSCode and Remote SSH 4.1. Remote Development with VSCode and Remote SSH

- 5.1. Live-to-Test, Test-to-Live Data Transfer 5.1. Live-to-Test, Test-to-Live Data Transfer

- 5.2. Cloud PBX(Virtual Switchboard) Integration and Usage 5.2. Cloud PBX(Virtual Switchboard) Integration and Usage

-

Case Studies

- 1. What is the Test Scenario? 1. What is the Test Scenario?

- Agriculture Case Study Agriculture Case Study

- Basic Organization Planning Study Basic Organization Planning Study

- Budget Planning Case Study Budget Planning Case Study

- Call Center - Service Transactions Case Study Call Center - Service Transactions Case Study

- Campaign Case Study Campaign Case Study

- Campaign Management Case Campaign Management Case

- Collection by Credit Card Case Study Collection by Credit Card Case Study

- CRM - Sales - Distribution Case Study CRM - Sales - Distribution Case Study

- Delay Interest Calculation Case Study Delay Interest Calculation Case Study

- Digital Transformation Case Study Digital Transformation Case Study

- E-Government Case Study E-Government Case Study

- Employee Authority Groups Case Study Employee Authority Groups Case Study

- Example Module Cases Example Module Cases

- Fabric Industry Case Study Fabric Industry Case Study

- Fashion Industry Case Study Fashion Industry Case Study

- Health Assurance System Case Study Health Assurance System Case Study

- HR Case Study HR Case Study

- Installment Sales Case Study Installment Sales Case Study

- Internal Requests Case Study Internal Requests Case Study

- Member Analysis Form Case Study Member Analysis Form Case Study

- Mixed Parcel Case Study Mixed Parcel Case Study

- Nuts Production Case Study Nuts Production Case Study

- Performance Evaluations Case Study Performance Evaluations Case Study

- Personnel Attendance Control System Case Study Personnel Attendance Control System Case Study

- Price Management Case Study Price Management Case Study

- Promotion Management Case Study Promotion Management Case Study

- Purchasing and Interwarehouse Transfer Case Study Purchasing and Interwarehouse Transfer Case Study

- Purchasing Case Study Purchasing Case Study

- Quality Control Processes Case Study Quality Control Processes Case Study

- Recruitment Case Study Recruitment Case Study

- Recruitment Case Study Recruitment Case Study

- Retail Product Collection Management Transactions Retail Product Collection Management Transactions

- Sales Order Case Study Sales Order Case Study

- Sales Process Case Study Sales Process Case Study

- Securities Case Study Securities Case Study

- Self Implementation Self Implementation

- Service and Warranty Case Service and Warranty Case

- Subscriber Management Case Study Subscriber Management Case Study

- Term Deposit Scenario Term Deposit Scenario

- Timekeeping Transactions Case Study Timekeeping Transactions Case Study

-

For Beginner

- A to Z E-Business Dictionary A to Z E-Business Dictionary

- Does my company really need an ERP? Does my company really need an ERP?

- Doing Business Above The Clouds - CLOUD COMPUTING Doing Business Above The Clouds - CLOUD COMPUTING

- How digital are your business processes? How digital are your business processes?

- How Long Do ERP Projects Take? How Long Do ERP Projects Take?

- Is my business ready for ERP? Is my business ready for ERP?

- Support and Report Problem Support and Report Problem

- What is an Application Server? What is an Application Server?

- What is ERP? What is ERP?

- What is IYS (Message Management System)? What is IYS (Message Management System)?

- Frequently Asked Questions

Serial Number in Production Processes

Serial numbers are a tracking method that allows tracking and viewing the history of products produced, purchased, sold, and in inventory.

In Workcube,

- Production,

- Purchase and Sales,

- Import and Export,

- Inventory input-output and receipts,

- Serial number tracking is provided in service and warranty processes.

PRODUCTION

In the production module, Serial No can be defined in two different areas.

1- Production Orders

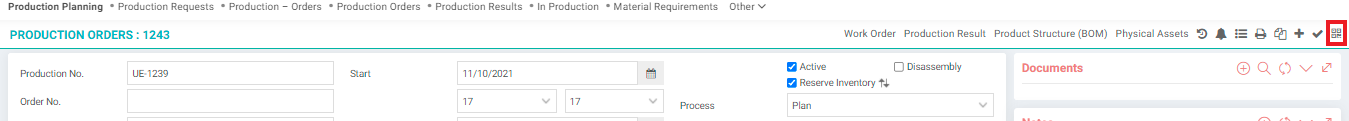

A production order is created from the ERP > Production > Production Planning > Production Orders page. From the detail of the Production Orders,

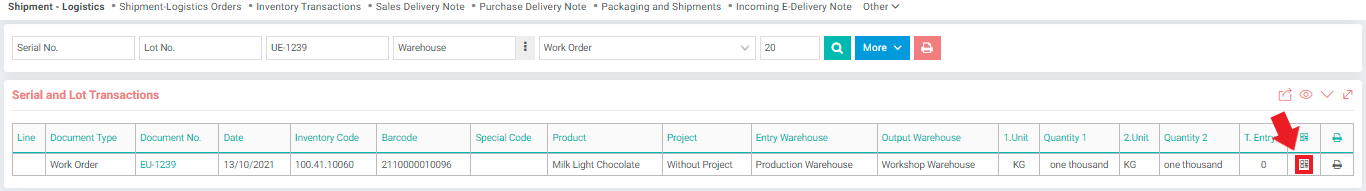

This selection leads to the Serial and Lot Transactions page.

Click on the "Warranty-Serial Numbers" icon at the end of the line. If there is no record on the line, "Serial Tracking" is not marked in the product detail.

- It is specified in the Product Serial No field on the Serial No Warranty Entry - Purchase page and save is pressed.

- The quantities of the series are displayed on the opened page of the product. Changes can be made in quantities.

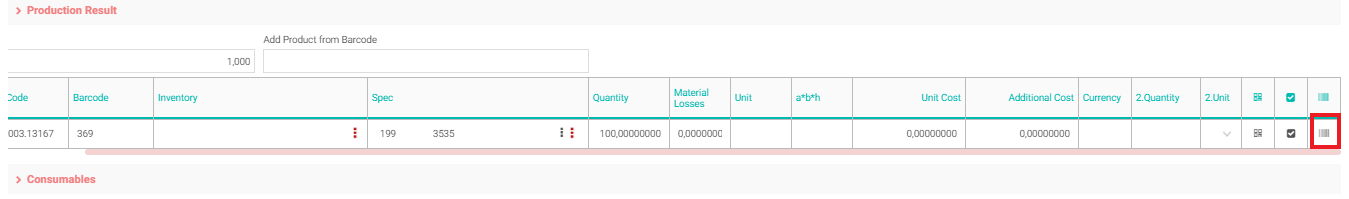

2-Production Result

From the ERP > Production > Production Planning > Production Results page, the production result detail screen is accessed.

- Production Result > Serial No button is clicked.

- Serial numbers are determined.

- The series and their quantities are checked and recorded.

WARNING!

In order to perform serial number tracking, go to Dashboard > System > General Settings > Company Flow Parameters.

- "Do you want to apply warranty tracking, repair and serial number?"

- "Serial Tracking - Check Return"

- "Do location-based serial entry / exit control" checkboxes must be checked as yes.

It is necessary to determine whether to follow the serial number for all products produced, bought and sold. (Products > Product Detail > Serial Number > Tracking) If the Followed box is not selected, serial tracking will not be performed.